Optical industry

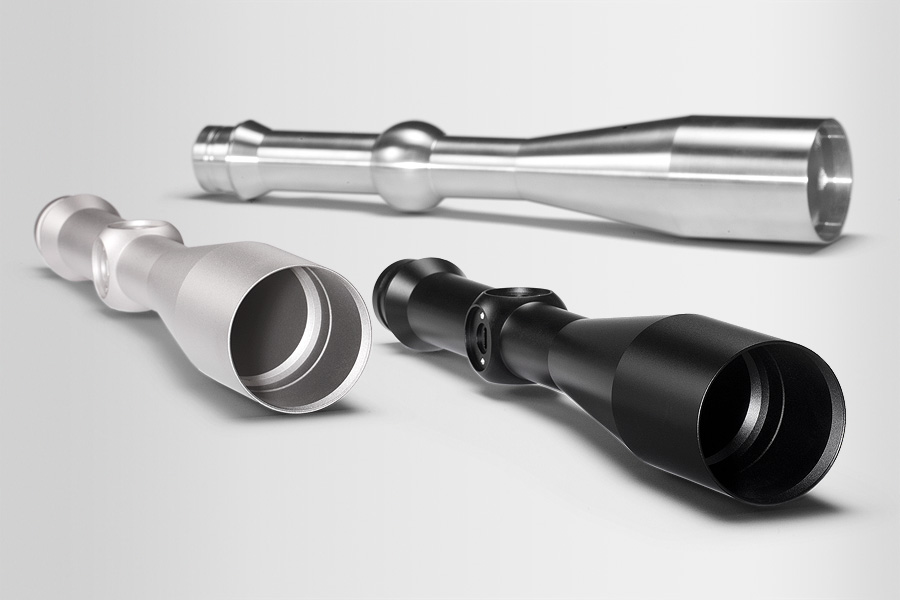

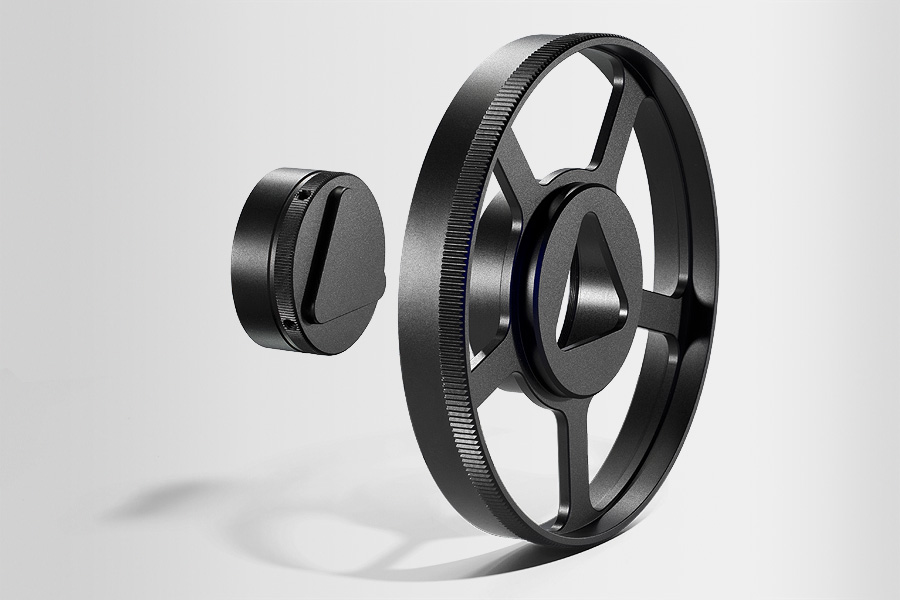

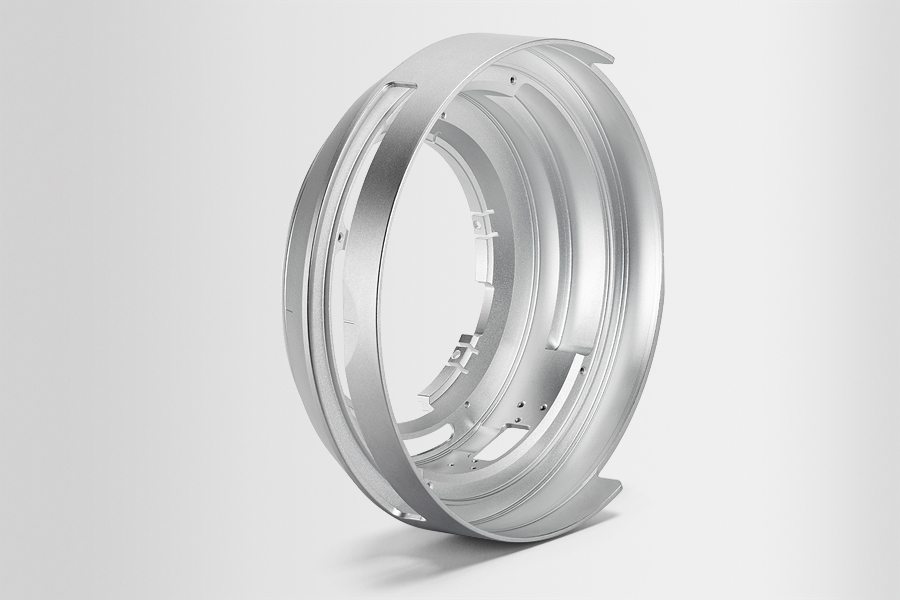

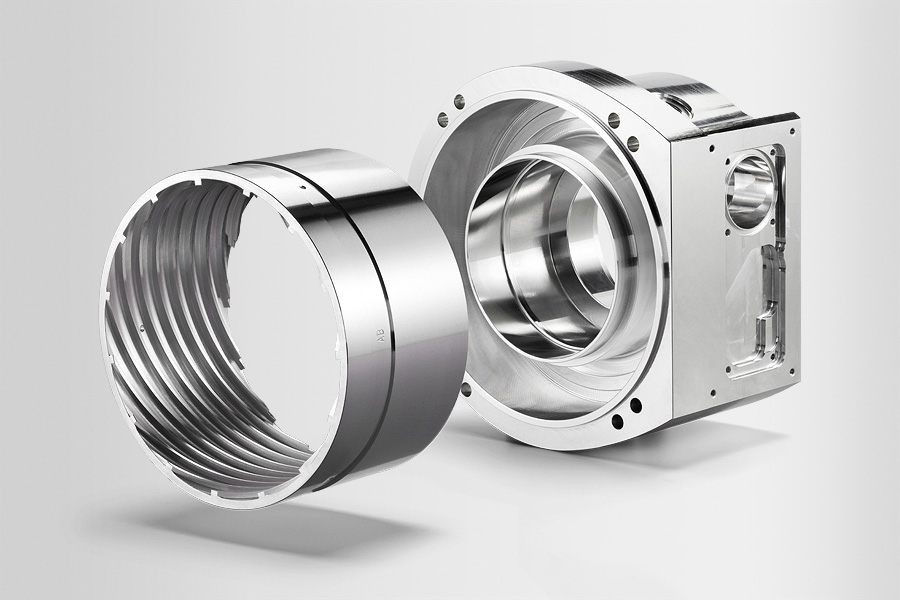

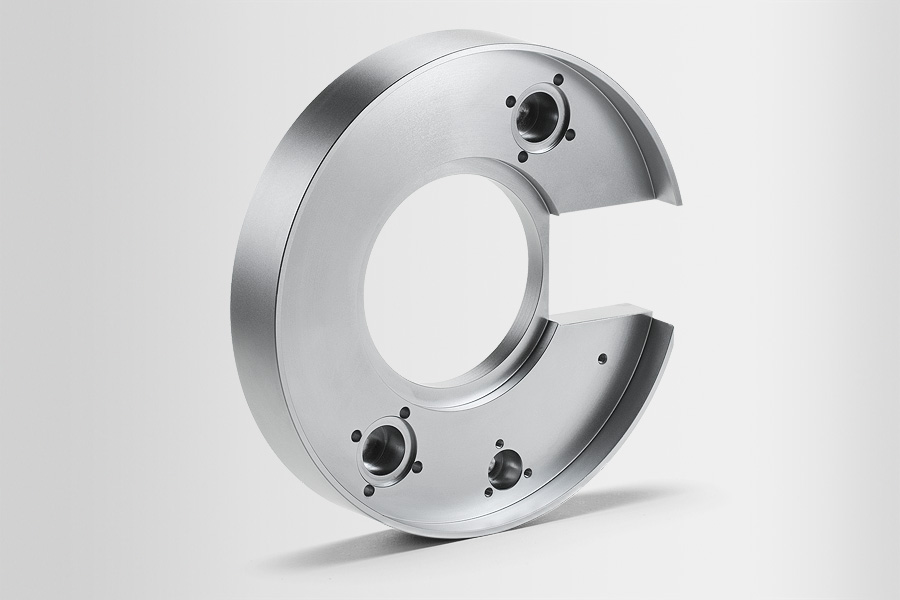

Extremely delicate designs – maximum surface quality

We have been a reliable partner of the optical industry for many years. We use our semi-automated and fully automated turning and milling centres to manufacture complex and sophisticated components, which are then finished in-house or in cooperation with our certified partners. If required, we can also help our customers with their production and/or assembly requirements by professionally assembling entire groups of components.

Our industry expertise:

- Tube bodies for telescopic sights

- Inner parts and attachments for telescopic sights and binoculars

- Lens mounts for film and photo cameras

- Machining down to the finest detail and highly decorative surfaces

- Assembly of complete groups of components / pre-assembly

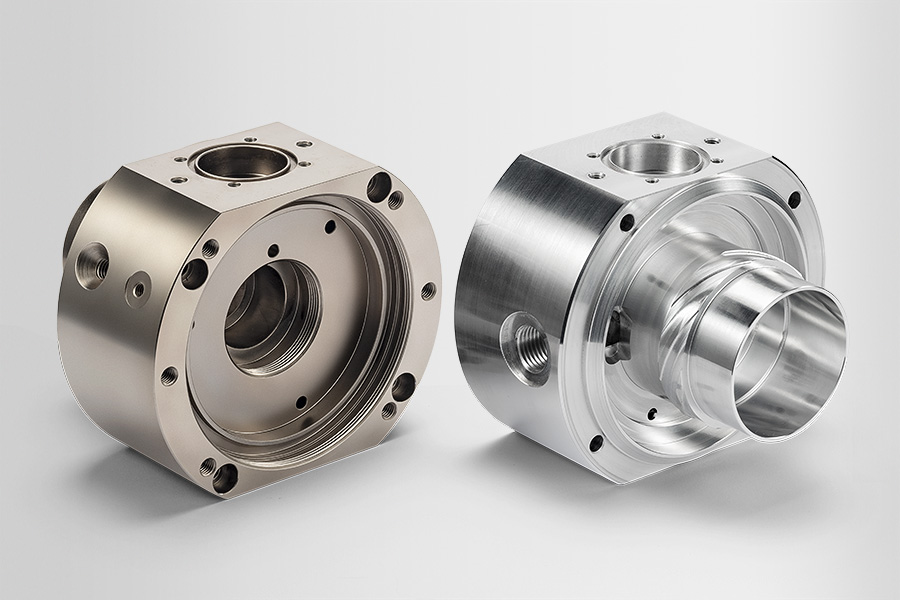

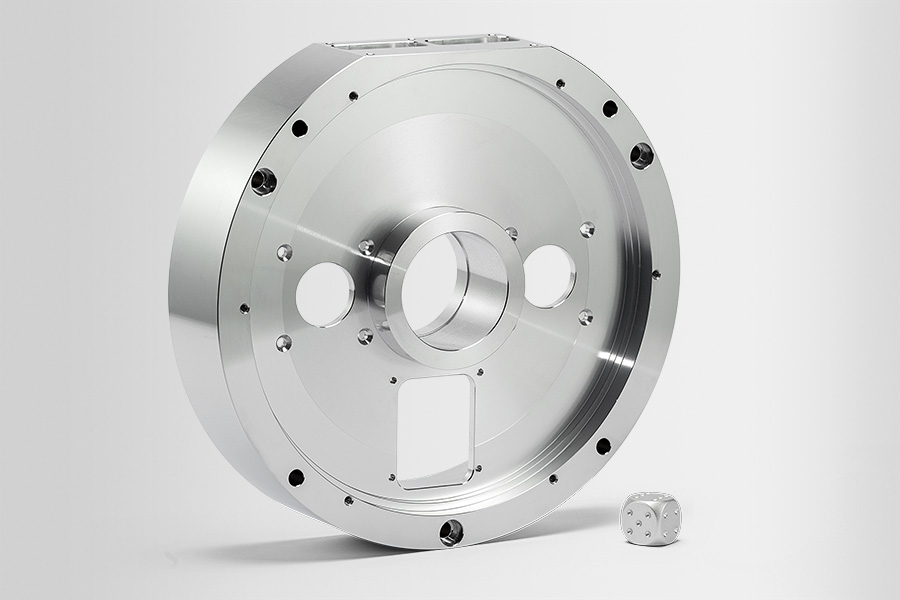

Vacuum engineering

Machining large volumes – maximum precision

We have been a preferred supplier of a number of leading vacuum pump manufacturers for many years. We manufacture mechanisms for vacuum pumps as single parts, prototypes and large-volume production parts. When doing so, we use our fully automated turning and milling centres to guarantee maximum precision alongside maximum machining volumes, short processing times and maximum cost-effectiveness.

Our industry expertise:

- Single parts, prototypes and large-volume production parts

- Maximum machining volume and maximum precision

- Fully automated turning and milling centres

- Turning of component diameters of up to 340mm

Medical technology

Highly sensitive components – maximum process reliability

We manufacture highly sensitive turned and milled components for medical devices and use measurement technology alongside our production activities to guarantee the quality of these parts. Our batch manufacturing and 100% documentation during the production process enable us to guarantee the full traceability of every single component, thus meeting the extremely high demands of the medical technology industry.

Our industry expertise

- Highly sensitive special parts for medical devices

- Batch manufacturing and full traceability

- 100% documentation of every component

- High-precision measurement technology alongside production activities

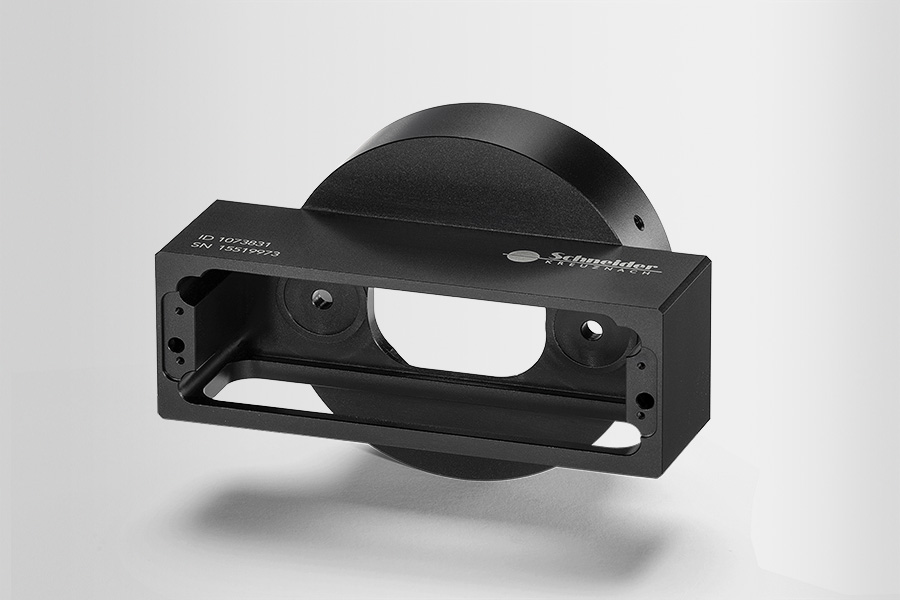

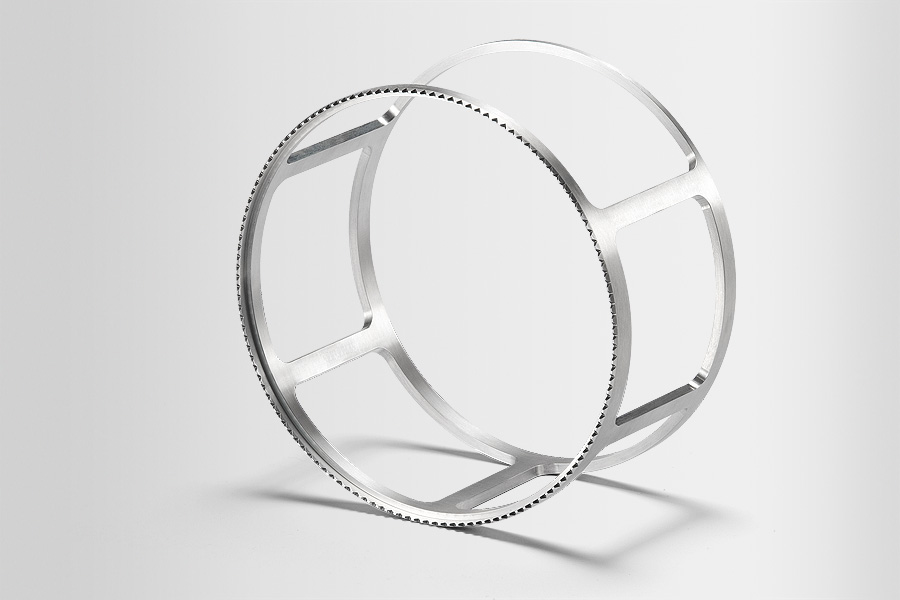

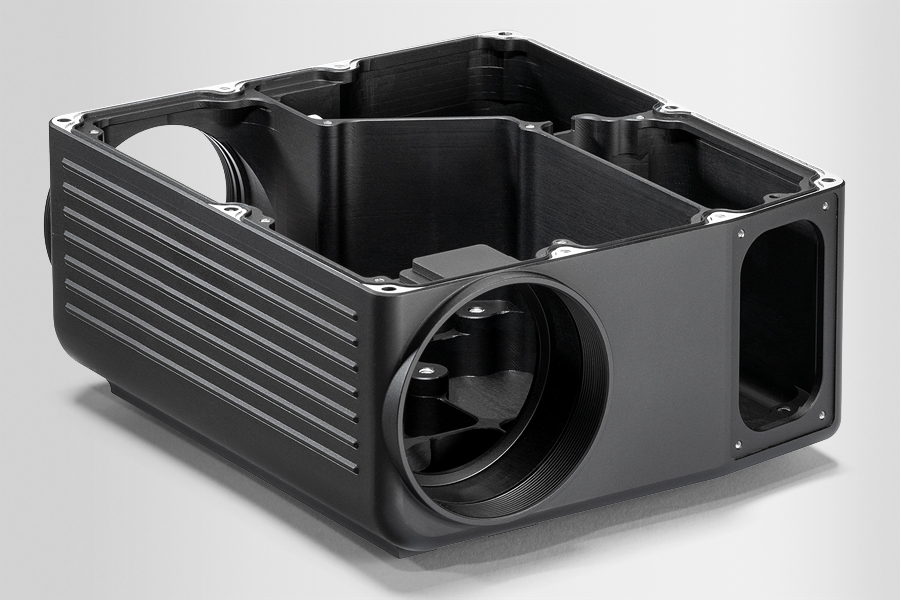

Defence

Lightweight construction – hard materials

We meet the extremely high demands of military engineering specifications. We manufacture lightweight housings and modules for mobile defence equipment, such as laser steering systems, night vision devices and scopes with very complex and delicate geometries. Beyond that, we cut ductile metal e.g. for sighting mechanisms for tanks and submarines.

Our industry expertise:

- Complex and delicate lightweight constructions

- Machining particularly hard materials

- 100% documentation and full traceability

- Very experienced, reliable partner

Acoustics industry

High-precision turned components – professional coatings

When it comes to the acoustics industry, achieving high machining precision and surfaces with a perfect appearance is the number-one priority. We manufacture turned components for renowned microphone manufacturers that meet the highest demands in terms of function and surface appearance. When doing so, we work in close cooperation with our long-standing electroplating partners to achieve perfect nickel-plating, chromium-plating and anodising results.

Our industry expertise:

- An extensive range of different coatings

- Long-standing electroplating partners

- Customer-specific evaluation methods for decorative surfaces

- Permanent staff awareness measures

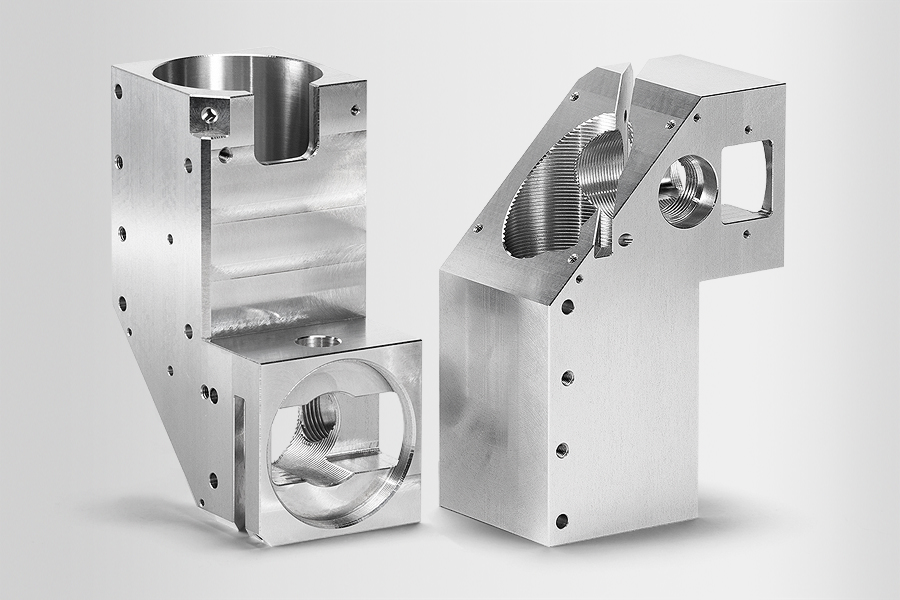

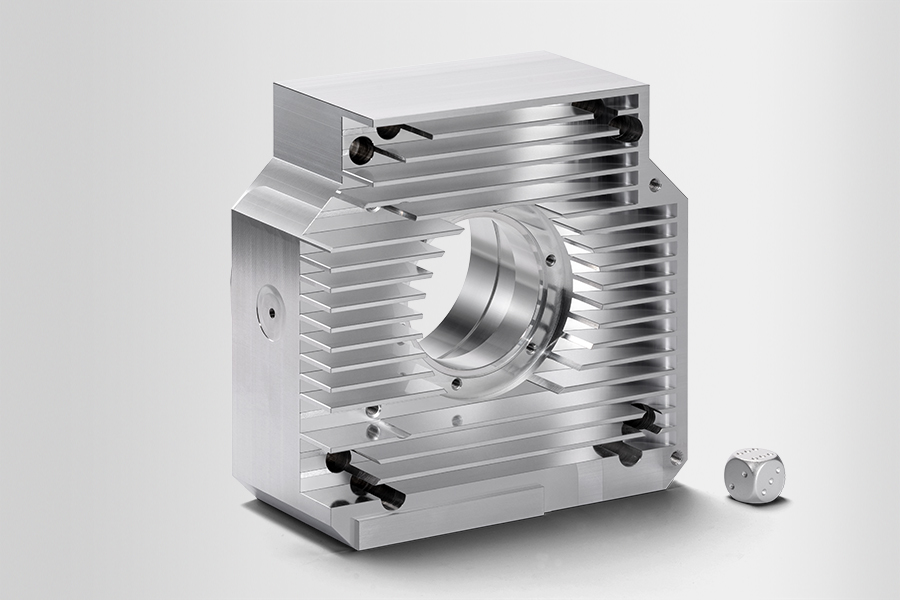

Semiconductor technology

Minimum processing times – extremely complex components

Semiconductor products play an essential role in the field of electrical engineering. In this industry, there is constant demand for shorter development times for new products and for the highly efficient manufacturing of products with small batch sizes. We meet this demand by providing optimal planning with short processing times using our high-precision turning and milling centres.

Our industry expertise:

- Highly complex component geometries

- Short processing times

- Small quantities also available

Mechatronics

Electronic components – professional assembly

We make life easier for our customers by offering professional assembly of complete groups of components, namely parts manufactured by us and electronic components supplied to us. When assembling groups of components, we guarantee the functional capability of sensitive mechatronics parts by observing all requirements and safety criteria at our special ESD-protected assembly workstations.

Our industry expertise:

- Assembly and pre-assembly of groups of components

- ESD-protected workstations

- Product-specific packaging

Automotive industry

Extremely high standards – precise implementation

As a prototype supplier for the automotive industry, we provide solid and reliable solutions that meet our customers’ high standards and demands. We use our semi-automated and fully automated turning and milling centres to manufacture prototypes in full compliance with precisely defined processes. When doing so, we use reliable just-in-time production to deliver the required quality.

Our industry expertise:

- Quick prototype manufacturing

- Full traceability of the supply chain

- Risk analysis based on common evaluation procedures

- Logistics to meet customer-specific requirements